CNC Machine

At Kushan Engineering, we offer precision CNC machining services tailored to your unique needs.

Our state-of-the-art CNC machines and experienced machinists ensure the highest quality components, whether you need prototypes, small batches, or large-scale production. With capabilities spanning metals, plastics, and composites, we deliver accuracy and consistency across diverse materials.

Metal Fabrication

We use various technologies to craft the perfect metal fabrication for you

we take pride in offering comprehensive metal fabrication services tailored to meet the diverse needs of our customers. With a commitment to quality and precision, we utilize a range of advanced technologies and techniques to deliver superior results. Our metal fabrication capabilities vary from Laser Cutting to Water Jet Cutting.

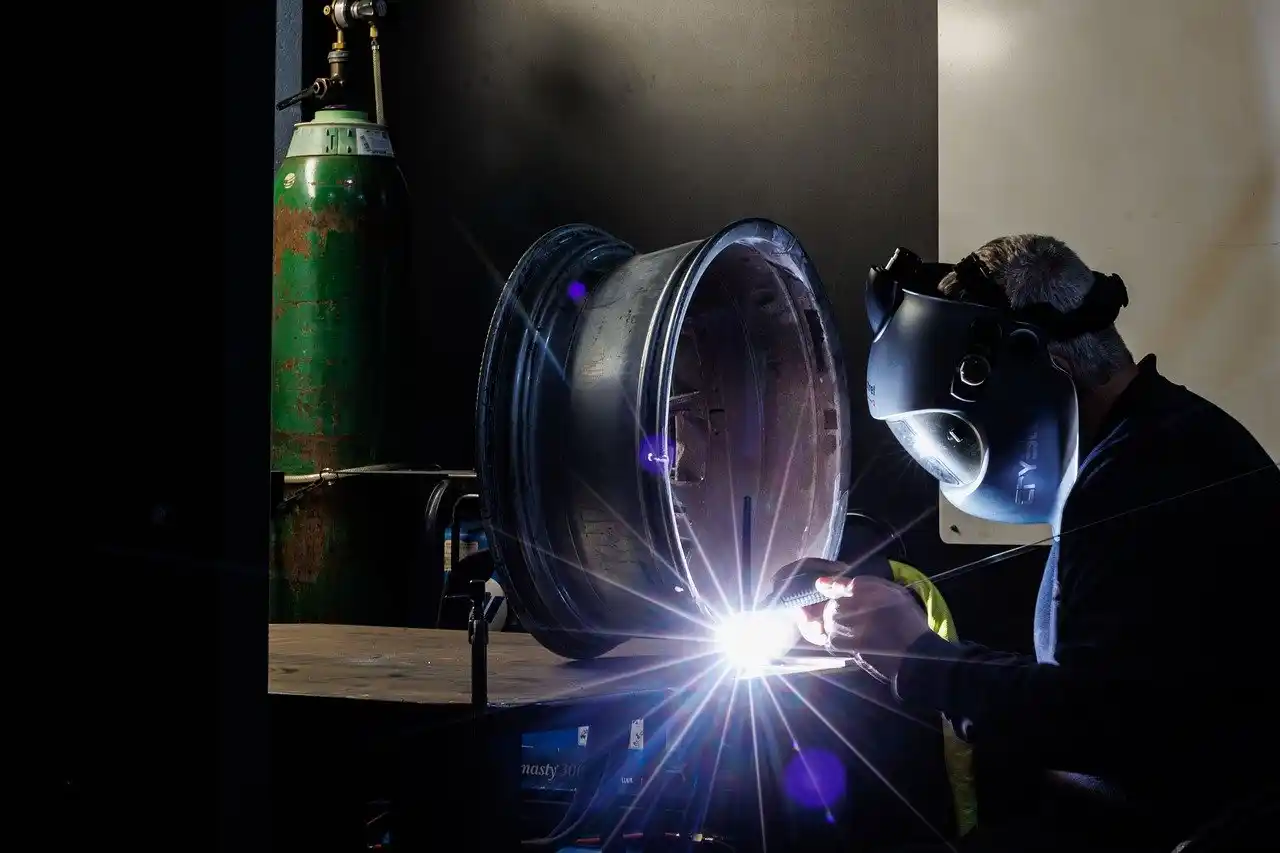

Welding

Our comprehensive welding capabilities include Manual , TIG, Arc, Gas, and Spot welding, allowing us to work with a wide variety of ferrous and non-ferrous materials. Whether you require intricate welds for precision components or robust welding for heavy-duty applications, we have the expertise and resources to deliver outstanding results.

- Laser Welding - Utilizing a focused laser beam for high-power, concentrated welds with minimal heat distortion. This is ideal for thin materials, tight tolerances, and creating clean, cosmetic welds on high-value parts.

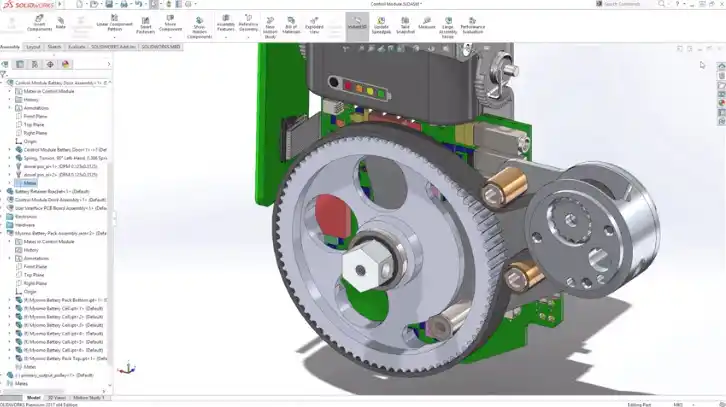

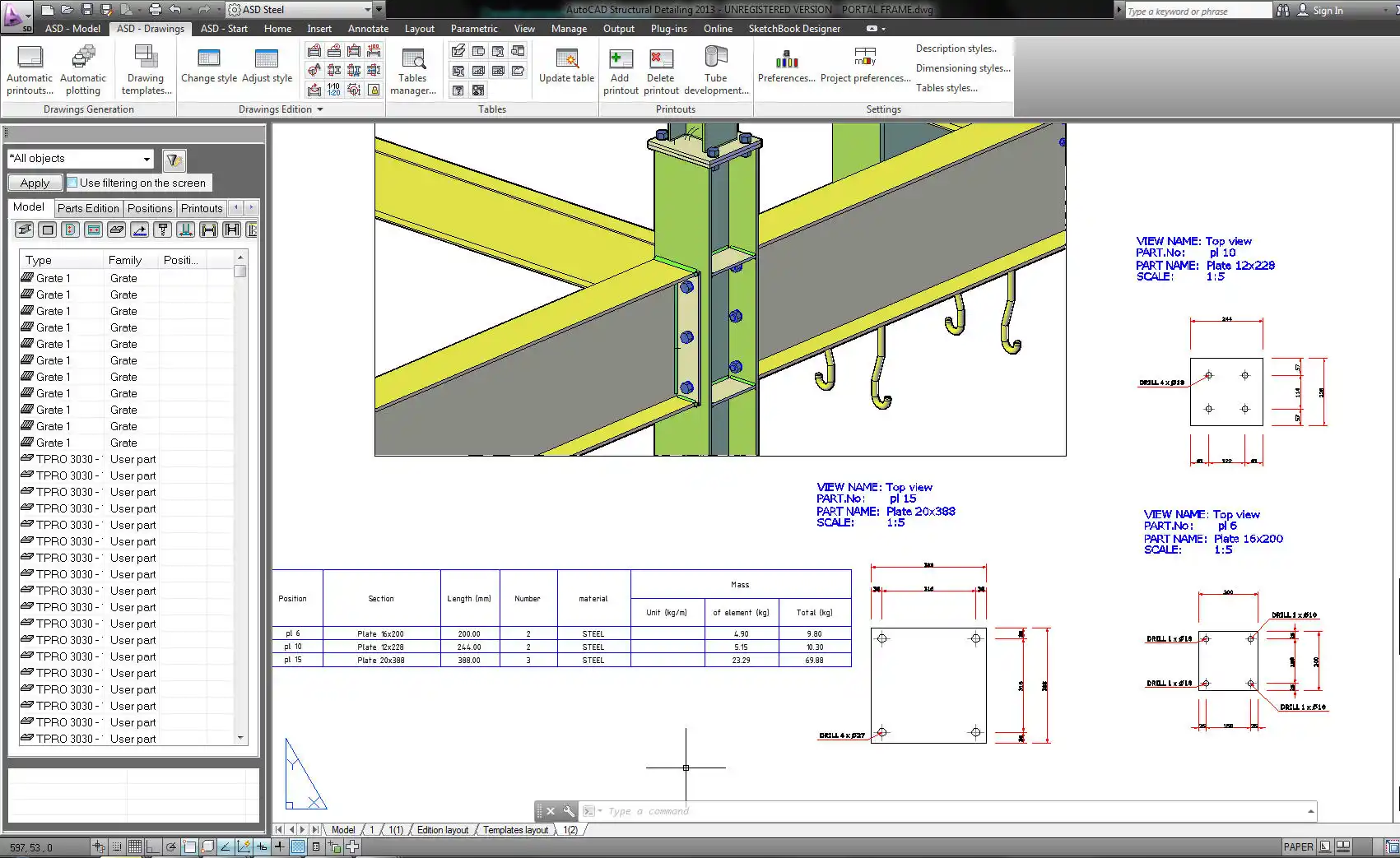

Product Designing

Our team of experienced designers are dedicated on briging your vision to life

With their expertise in product design and development, our designers can take your ideas and transform them into tangible products that meet your specifications and exceed your expectations. From conceptualization to prototyping and final production, we work closely with you to ensure that every detail is carefully considered and meticulously executed.

We utilize a range of design software tailored to meet diverse client requirements. From rudimentary sketches to detailed blueprints, our team can adeptly translate any client input into actionable designs. Here are some of the software tools we employ:

- SolidWorks: Renowned for its robustness and versatility, SolidWorks is a 3D CAD design software widely favored in engineering and manufacturing. It facilitates the creation of intricate models, assemblies, and drawings with precision and efficiency.

- AutoCAD: A staple in the design industry, AutoCAD is a versatile drafting software used for 2D and 3D design and documentation. Its intuitive interface and comprehensive toolset make it ideal for generating precise technical drawings and architectural plans.

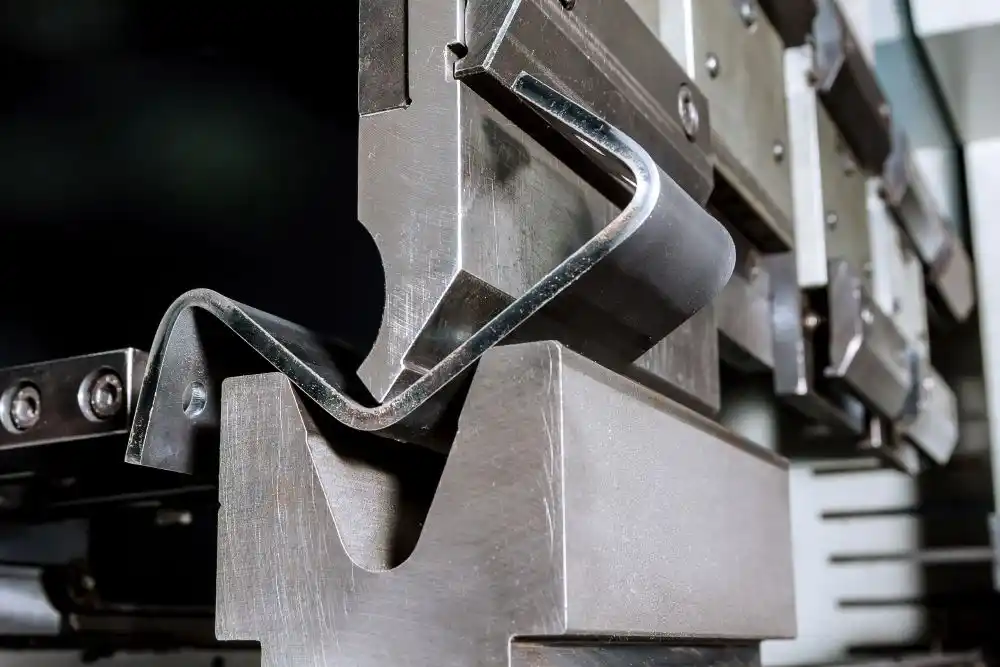

Steel Bending, Cutting & Rolling

We use various technologies to craft the perfect metal fabrication for you

Experience our large steel sheet bending and cutting services, tailored to meet the diverse needs of our valued customers. At Kushan Engineering, we utilize advanced CNC laser machines for intricate cuts on smaller steel sheets, ensuring accuracy and efficiency. For larger steel sheets, we employ a specialized range of machinery dedicated to cutting and bending, guaranteeing precise results that adhere to your specifications.

Sheet Rolling -

- L Angle

- Flat Iron

- C Channel

- H Iron

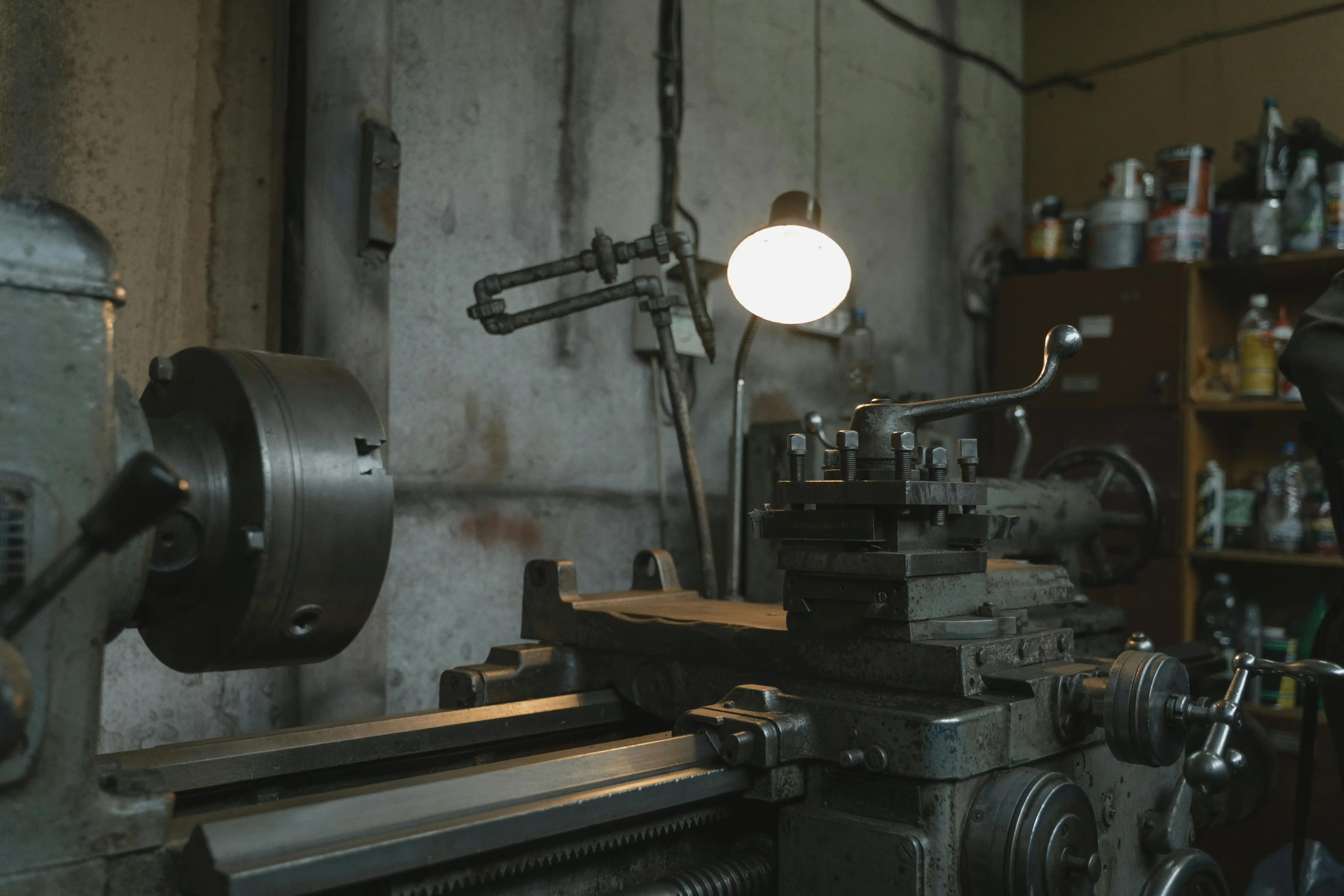

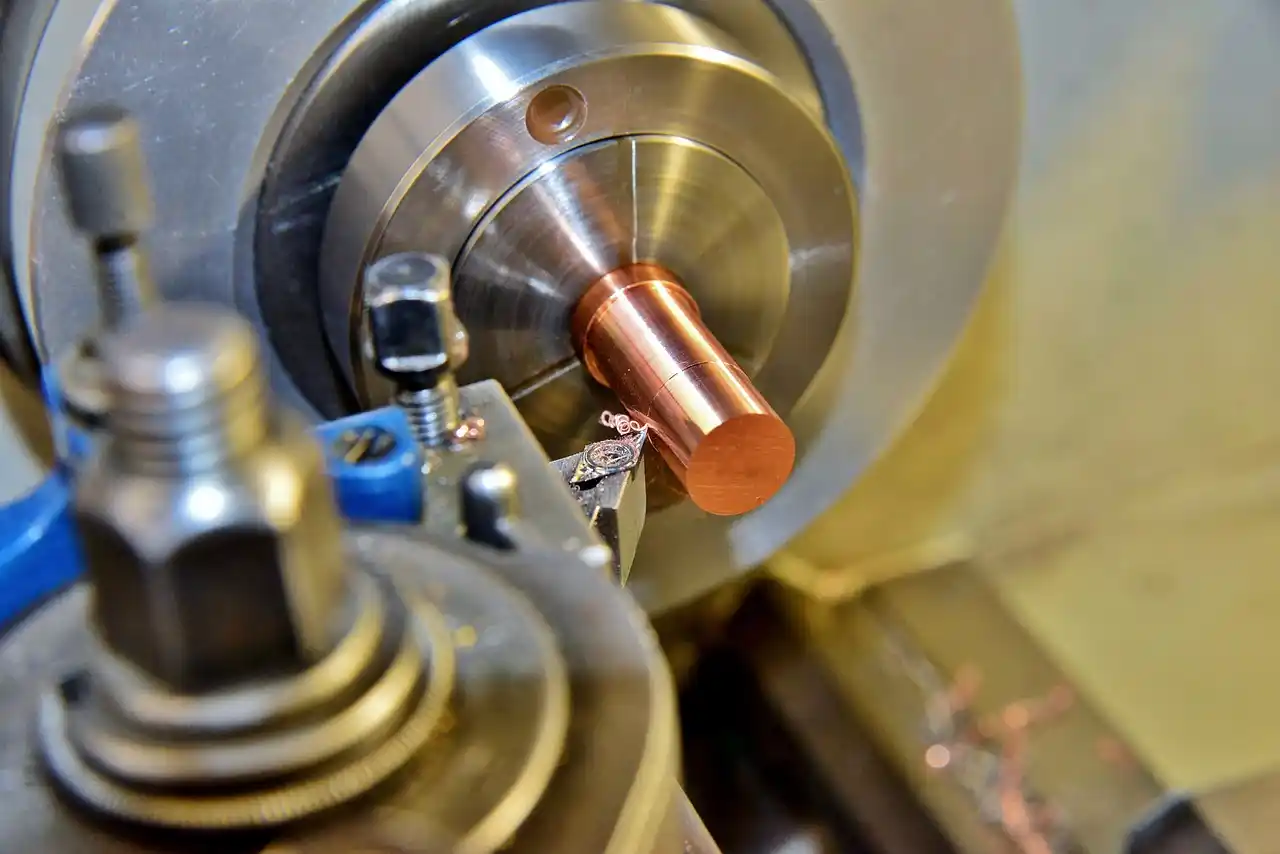

Lathe & Milling Works

Our team of experienced designers are dedicated on briging your vision to life

Our machine shop is equipped with state-of-the-art CNC lathes and mills, allowing us to provide precise and efficient turning, facing, boring, drilling, and milling services for your steel components. We can handle a wide range of sizes and complexities, ensuring your parts meet exact specifications. Whether you need prototypes, short runs, or high-volume production, we have the expertise and capacity to deliver.

- Lathe Works:

- Turning: Creating cylindrical shapes of various diameters and lengths.

- Facing: Squaring off the ends of a workpiece.

- Boring: Enlarging existing holes or creating new ones with tight tolerances.

- Drilling: Creating precise holes at various depths and angles.

- Milling Works:

- Milling: Creating flat surfaces, pockets, slots, and contours on various planes.

- Facing: Similar to lathe facing, but for flat surfaces on non-cylindrical workpieces.

- Drilling and Tapping: Creating and threading holes for secure fastening.

- Angled Machining: Machining surfaces at precise angles.